Jul 12th 2022 - Monica Cunanan

How to Properly Clean Candy Machine

You would probably see servings of fluffy cotton candy popular at sports stadiums, concession stands, amusement parks, and even parties. Everyone loves them! If you are someone who owns a commercial cotton candy machine for business or parties, you would know important it is to keep them clean before and after use. This blog shows you how to do exactly that and more.

Want to know how to use one and create cotton candy in minutes? Check out this guide!

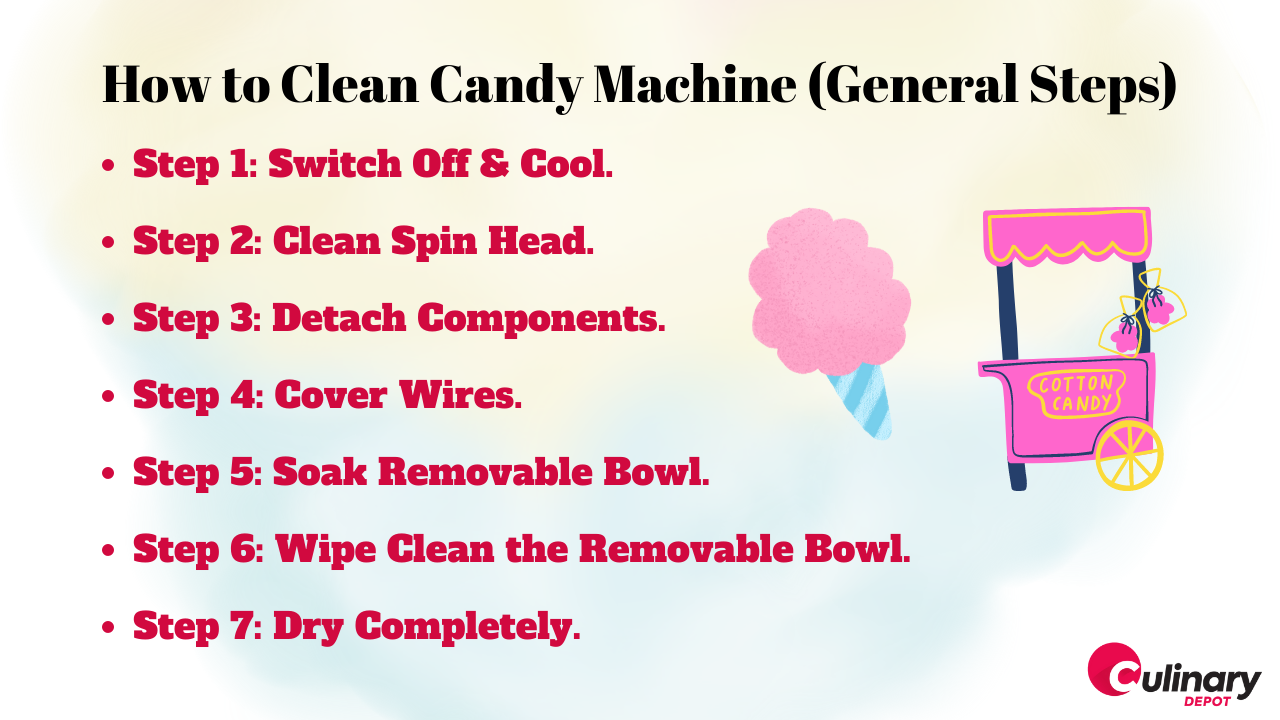

How to Clean Candy Machine

- Step 1: Switch Off & Cool. After using the machine, be sure to turn it off and unplug it. Cool down all components to a temperature that is comfortable to touch.

- Step 2: Clean Spin Head. Do this with water and a non-abrasive cloth. After using the damp cloth, dry Completely.

- Step 3: Detach Components. Detach the components such as the spinning head and remove the floss head

- Step 4: Cover Wires. Now that the wires are exposed, cover the opening with a towel to prevent any outside contaminants.

- Step 5: Soak Removable Bowl. You may need to soak the bowl in warm water if you've been using it heavily.

- Step 6: Wipe Clean the Removable Bowl. Do this with mild soap and a Non-abrasive cloth before rinsing.

- Step 7: Dry Completely. After all, the parts are completely dry, reassemble the commercial cotton candy machine.

How to Clean Candy Floss Spinner:

The floss spinner is where you place different flavors of floss sugar where it can spin to produce servings of cotton candy. Some hardened sugar build-up along the sides of the stainless steel bowl is normal. This can be broken away and/or dissolved away with warm water.

These are the detailed instructions:

- After using, it is recommended to clean your commercial cotton candy machine with a tough cleaner, such as a decarbonizer/ degreaser/stainless steel cleaner solution

- If you want to fully remove all the cleaning solution from the spinning head, turn off the heat first. Then spin the spinner without the heat. Repeat with water to flush the cleaning solution through.

- After rinsing it, turn off the motor and then use a clean cloth to wipe. This is important for maintaining food safety and extending the longevity of the unit.

- Do not submerge the device completely in water when cleaning. The appliance should not be cleaned with a water jet.

How to Clean Candy Floss Cart:

- Using a damp soft cloth, wipe down the cart to remove residual sugar. Don't use harsh abrasive cleaners because they will damage the surface.

- If you follow the proper cleaning instructions, then the operation of the unit will not be affected. Don't use an automatic dishwasher for washing the parts.

Machine featured: Winco CCM-28M Showtime Cotton Candy Machine

How to Set up Your Cotton Candy Machine:

Make sure to consolidate with your manufacturer's assembly manual.

- Attach the bowl to the base using the four clamps located on the side of the base. Make sure the bowl isn't touching the heating head. If you have the floss bubble shield, place it on top of the bowl.

- Plug the power cord into the base and then plug it into a grounded electrical outlet. Turn both the “power switch” and the “heat switch” to the ON position. Both switches will light when they're turned on. WARNING: Ensure that you have the ideal voltage for your unit.

- Add floss sugar into the central floss head by using the floss scoop provided.

- Add floss sugar directly into the well in the heating head using the floss scoop. Don't overfill.

- As the heat comes up, the cotton candy will begin to spin in the bowl.

- As the cotton candy builds up, it will eventually come out through the top. To get the cotton candy, you'll need to collect the cotton candy whisps as it comes out of its top with candy sticks or cotton candy cones.

- Allow the machine to cool down for 15-20 minutes after an hour of continuous use.

Pro-tip: If you are hosting a small party, opt for reusable cones. For faster rates of cotton candy production, Disposable cones will be ideal especially if you have a business selling carnival-style cotton candy.

Reasons to Clean it Regularly

Treating your machine well is the best way to ensure it lasts as long as possible. There are several reasons for which you should clean your commercial cotton candy machine frequently.

If you own a Cotton Candy Machine, you probably use it often! It’s not always easy to remember that there are other parts of it that aren’t as accessible unless you actually take a good look at them. The area around the motor and base needs cleaning as well. Cleaning these areas will help prevent the motor overheating and reduce the chances of burnt sugar.

Hot, melted sugar can attract airborne particles like dirt and dust.

How often should you clean your cotton candy machine?

Cotton candy machines should always be cleaned at least once per week, ideally after every single use.

If you haven't cleaned your machine for a while, start by soaking the individual items in hot water. This will help dissolve any hardened sugar. This is important for your central heating head because it has tiny holes that are easily blocked.

Some commercial-grade cotton candy makers have vertical airflow ports that can get clogged from extended use..

Tips for Keeping a Cotton Candy Machine in Good Working Order

How Much Floss Sugar to Use?

One tablespoon of floss sugar is a good amount for one serving. However, you should check your instruction manual because some machines can produce different amounts of floss candy per minute

How long to pre-heat the machine?

This would also depend on the instruction manual. Before putting the floss in the machine, let it run for 10-15 minutes. To check, you can hover your hand over a spinning wheel, you should feel some warmth.

The sugar heats more even this way and so doesn't clog the machine as often.

What to Do If Hard Candy Is Not Melting Evenly?

If you will be using hard candy, you might need more time to preheat the machine. You can try to evenly distribute the hard candy in the spin head. The best way to do that is to smash the candy to bits before placing it on the central heating head.

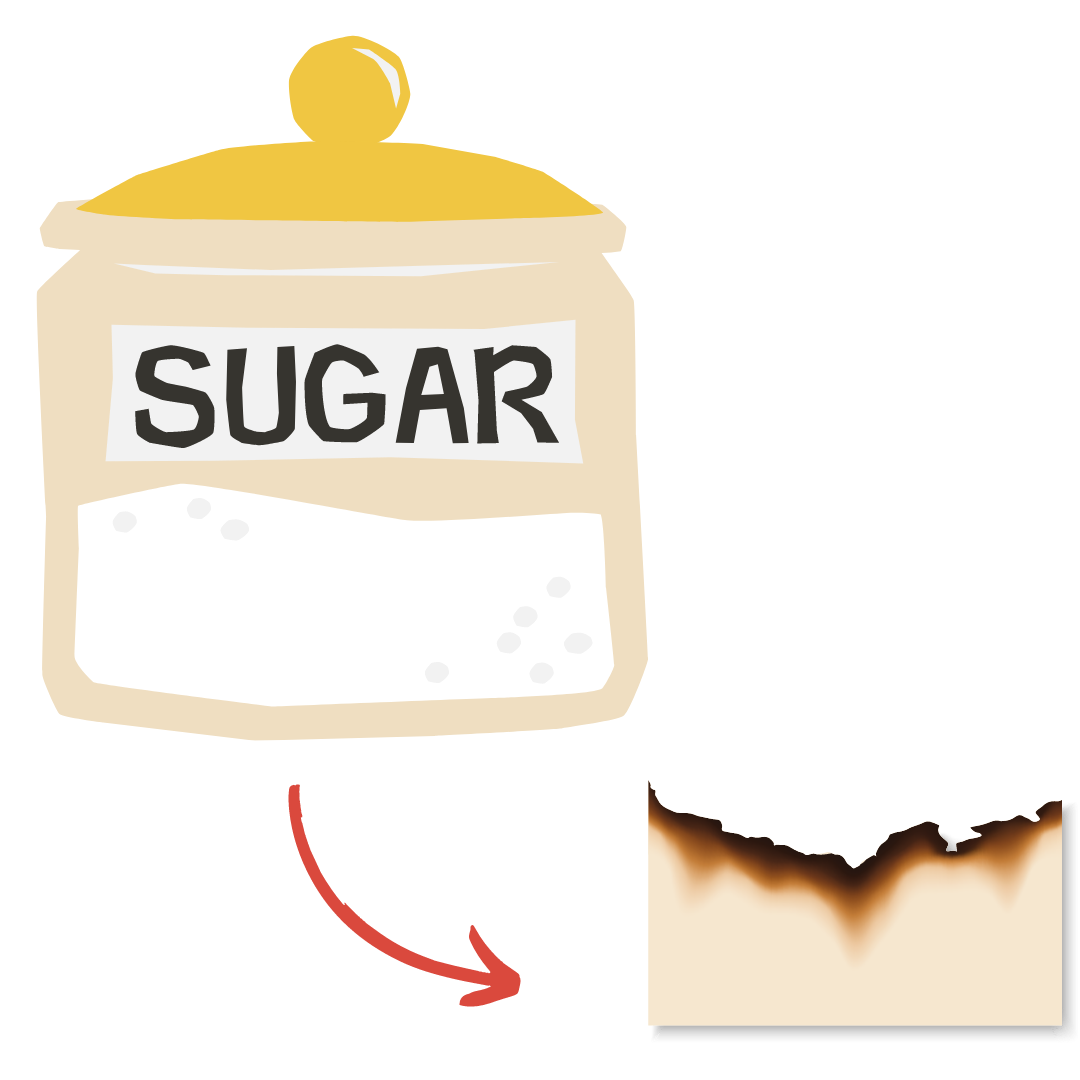

Never Use Sugar Finer Than Powdered or Caster

The smallest to largest sugar goes from powder to granules. Caster and powdered sugars are too fine for a cotton candy machine. If you've already tried it, you might notice that it burns easily. For these types of sugar, use them for other types of confectionery and not cotton candy.

How to Clean Burnt Sugar?

Soak in vinegar for 10 minutes, then use an abrasive pad. You can also use hot water to dissolve the burnt sugar. Cleaning burnt sugar is important because it prevents further damage from occurring. When sugar caramelizes to a dark brown color, it is easy to clean off compared to letting it heat for a long time until it turns black. If you notice any browning along the inside of the spin head, take care of that right away!

Thinking of getting a Cotton Candy Machine?

Here at Culinary Depot, we carry different types of cotton candy makers and cotton candy machine accessories that are perfect for any occasion. Contact us or visit our online store for more information about any commercial machines to serve that delicious cotton candy to your family, or even customers!